Fixing Blurry Barcodes: How to Improve Scan Quality

A barcode is designed to be simple: a quick scan, a beep, and onto the next item. But you’ve likely seen—or worse, experienced—the following: the beep goes silent, a worker fumbles with the scanner, flips the item over, and tries again to no avail. The culprit? A blurry barcode.

Blurry barcodes may seem like a minor inconvenience or a small glitch in your business, but they can quickly snowball into shipment delays, frustrated workers, annoyed customers, and even lost revenue. In inventory management, barcode blunders can derail your workflow, misplace your stock, or even throw your supply chain into chaos. But here’s the good news: you don’t have to picture these worst-case scenarios, and these blurry barcodes don’t have to be your nemesis.

In this article, we'll help you tackle blurry barcodes so you can keep your inventory operations running smoothly. You’ll learn:

- The main causes of a poorly printed or blurry barcode

- How to improve barcode quality

- Best practices for creating barcodes

The Main Causes of Blurry Barcodes

A barcode is more than just a set of black lines or cells, letters, and numbers; it’s a fundamental tool that improves data accuracy and efficiency in inventory management. In a nutshell, barcode errors—although fixable—can ripple through business processes. But before we delve into the solutions and actionable fixes, let's first explore the reasons behind the blur. Here are the common causes of blurry barcodes:

1. Poor Printing Quality

Blurred lines in barcodes can result from improper printing settings or low-resolution printers. When a printer has low resolution, the lines of a barcode may appear smudged, rendering them unreadable. Additionally, printing devices that haven’t been calibrated or properly maintained can make these issues even worse, leading to inconsistent or poor-quality barcode output.

2. Environmental Factors

In retail, logistics, and manufacturing, factors like repeated reloads, long-distance movement, and environmental conditions (like heat, humidity, and even exposure to chemicals) can affect barcode visibility. Moreover, glare and poor lighting might also interfere with the scanning process of the labels.

3. Incompatible Label Materials

One of the most overlooked causes of blurry barcodes is the use of the wrong type of label materials. Labels that are not designed for thermal printers may fail to hold the ink or heat transfer properly, resulting in faint barcodes. Whether you manage a small retail store or a big warehouse, it’s important to consider your business needs to identify the appropriate type of printer and materials for your inventory.

4. Scanning Distance

Scanners—whether handheld or long-range—are designed to operate within specific ranges. Scanning the item too far from or too close to the scanner may affect the readability of the barcodes.

You should use barcode scanners based on the range that meets your environment:

- High-density barcode scanners - used to read barcode sizes down to 3 mm

- Standard range scanners - suitable for both large and small barcodes in retail stores, warehouses, stadiums, etc.

- Extended range scanners - capable of scanning low-density barcodes from distances up to 50 ft; ideal for items on high warehouse shelves

How to Improve Your Barcode Quality

Now that you know the main causes of blurry barcodes, it’s time to explore the practical ways to improve label quality. From quick printer adjustments to choosing the right tools, these tips will help make your barcode labels clear and easy to scan.

▶︎ Adjust Your Printer Settings

Check whether the barcode issue is an isolated case or a bigger problem affecting the whole batch. If it’s the latter, make sure to check the conditions of the printer and the ink cartridge. Configure your printer settings by selecting the appropriate resolution and adjusting the print speed. Printing too quickly may result in distorted barcodes, while slower speeds typically produce more precise output.

▶︎ Proper and Regular Maintenance

The dust, ink residue, and debris that accumulate over time may affect the print quality, leading to incomplete or smudged barcodes. You can prevent this by regularly cleaning the components of the printer, including the rollers and printheads. Routine inspections can also help identify worn-out parts that need replacement.

▶︎ Choose the Right Label Material

Choosing the right label material for your printer is important, especially if your products are exposed to harsh conditions such as extreme temperatures and high humidity. Excessive heat can cause labels to peel or warp, while extremely cold temperatures can make the material brittle. High humidity can also lead to smudged or soggy labels, making them difficult to be read by scanners.

Additionally, be sure to check the adhesive quality of the labels to ensure that they can remain intact during handling and transport to avoid misalignment and peeling.

▶︎ Improve Your Label Design

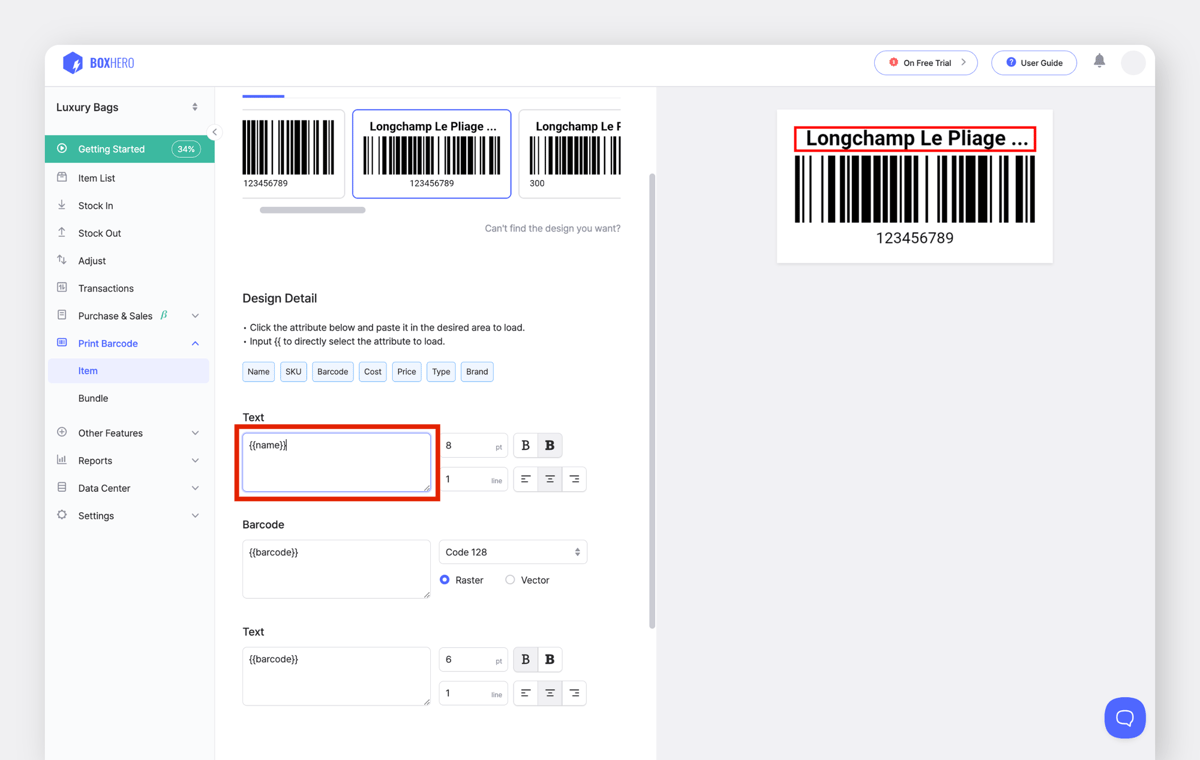

The real value of barcodes lies in the information they hold, which can include details like an item's brand, color, price, and more. That’s why using inventory management software can help: With BoxHero, you can design your own labels based on your needs and preferences to print high-quality barcodes.

Best Practices for Creating Barcodes

Using the right tools, following industry standards, and adopting smart solutions can help you create clear and scannable barcodes. Here’s a quick guide to the best practices for generating barcodes:

Consistent Barcode Formatting

Make sure that your barcode format follows the industry standards and is appropriate for its intended use. While there is no single universal barcode format, various specifications determine how and why they were developed. For instance, high-density codes are ideal for industries requiring a high level of security, such as defense, government, and aviation. Meanwhile, other types are widely used in retail stores, warehouse sorting, and logistics.

There are two main types of barcodes: one-dimensional (1D) or two-dimensional (2D). 1D barcodes are typically composed of a series of black vertical lines of varying widths, often accompanied by characters. Some of the commonly used 1D barcodes are:

- Universal Product Codes or UPC: also referred to as UPC-A; widely used in retail settings.

- European Article Number (EAN): designed for Point-of-Scale systems; commonly used in convenience stores.

- Code 39: used across various industries such as aviation, healthcare and defense.

- Code 128: a high-density complement to Code 30 used in logistics, defense, automotive, and manufacturing.

If you have scanned a QR code with your mobile device before, you already know how 2D barcodes differ from their 1D counterparts. Unlike 1D barcodes, 2D barcodes store information in both vertical and horizontal directions. Some of the most commonly used 2D barcodes are:

- QR Codes - made up of square patterns that store encoded data and can be easily read by digital devices.

- Data Matrix - typically square or rectangular, these high-density codes consist of light and dark cells arranged in a grid or matrix.

- PDF417 - this 2D barcode symbol can encode large amounts of information across multiple codes and is suitable for a variety of applications such as mobile boarding passes, patient identification bracelets, and state-issued identification cards.

Use High-Quality Scanners

Scanners have improved over the years so that they can now read barcodes that are damaged, smeared, or printed on tough surfaces. Before investing in a scanner, make sure you consider some key factors for your inventory management needs:

- Environmental Factors: For resistance to water, dust, fall damage, or lighting conditions, laser barcode scanners, charged-coupled device (CCD) scanners, or linear image barcode scanners are great options.

- Mobility: If mobility is your priority, choose from fixed, portable batch, or wireless scanners.

- Range: For specific scanning ranges, consider high-density, standard, or extended-range scanners.

Implement Software Solutions

Last but not least: Integrating a software solution is key to efficient and accurate inventory management. BoxHero offers comprehensive features such as:

- Barcodes: generate, scan, and print barcodes within a single system.

- Attributes: record custom details of your products like brand, color, and size for easy categorization and tracking.

- Low stock alerts: get notifications to prevent stockouts and maintain optimal inventory levels.

- Purchases & Sales: easily create and manage purchase orders and sales invoices.

- Sales Analysis: get detailed analytics to identify sales trends and patterns to make smarter business decisions.

What’s Next in Barcode Technology

According to a recent report by Future Market Insights Inc., the barcode scanner market is projected to reach an industry value of $14.88 billion by 2034. The market is anticipated to grow at a compound annual growth rate (CAGR) of 6.52% in the next 10 years.

This growth is driven by the increasing importance of barcodes in businesses across various industries. Beyond just speeding up the checkout process by scanning items, barcodes also help to keep track of sales and transactions. The data generated from barcode scanning can help business owners identify consumer trends and behaviors, which are important for making strategic business decisions.

Clear Barcodes, Clear Results

Fixing blurry barcodes doesn’t always have a single, clear-cut solution. It might involve quick fixes like adjusting the printer settings or more complex solutions, such as choosing the right label materials and scanning devices.

With the right tools (barcode scanners, printers, and a software-based inventory management solution), you’ll be well-equipped to manage your inventory and grow your business.

At BoxHero, we make barcode generation simple. Sign up today and explore our features to scan, design, and print your unique barcodes.