The Future of 3PL: Key Trends in Logistics

Third-party logistics (3PL) providers play a vital role in keeping the global supply chain running smoothly, offering expertise in transportation, warehousing, and distribution.

As businesses face challenges like managing inventory and handling last-mile delivery, 3PLs have become trusted partners, helping to cut costs and improve efficiency.

With the 3PL market expected to grow to US $1.9 trillion by 2030, staying competitive is key. In this article, we’ll explore the major trends shaping the industry, from new technology adoption to sustainability efforts and the growing use of AI and predictive analytics.

What is 3PL?

Third-party logistics, commonly abbreviated as 3PL, are specialized companies that manage the logistics operations for businesses that prefer not to handle these functions in-house. These activities typically include warehousing, inventory management, order fulfillment, and transportation services.

By outsourcing these responsibilities, companies can focus on their core business areas such as product development and customer engagement.

How do 3PLs work?

Here's a step-by-step overview of how third-party logistics (3PL) providers typically operate:

- You supply your products to the 3PL provider.

- The 3PL stores your products in their warehouse facilities.

- They log and manage the inventory, keeping track of stock levels and handling inventory control.

- When orders are received, the 3PL handles the picking of items from inventory.

- The selected items are then packed securely to prepare for shipping.

- The 3PL coordinates the shipping process, ensuring that orders are dispatched and delivered to the correct addresses.

- They manage returns and exchanges, processing items that come back and restocking them or disposing of them as needed.

- The 3PL may provide customer support for shipping and delivery inquiries.

- Regular reports and analytics are provided, offering insights into inventory levels, order status, and logistics performance.

Importance in Modern Supply Chains

3PL providers have become integral to modern supply chains. Their importance extends far beyond simple storage and transportation. Here's why 3PL is crucial for businesses today:

- Global reach: 3PL providers often have an extensive network of facilities and partners worldwide. This allows you to expand your market presence without the need to establish your own international infrastructure.

- Flexibility: Market demands can change rapidly. 3PL services offer the flexibility to scale operations up or down quickly, helping you respond to seasonal fluctuations or unexpected market shifts.

- Technology integration: Many 3PL companies invest in advanced technologies that you might find costly to implement on your own. These include warehouse management systems, transportation management software, and real-time tracking tools.

- Risk mitigation: By distributing your inventory across multiple 3PL locations, you can reduce the risk of disruptions due to local issues or natural disasters.

- Regulatory compliance: International shipping involves complex regulations. 3PL providers specialize in navigating these requirements, helping you avoid costly mistakes and delays.

- Cost efficiency: With 3PL, you can convert fixed costs (like warehouse leases and staff) into variable costs based on your actual logistics needs. This can significantly improve your cash flow management.

- Customer satisfaction: In an era where rapid, accurate deliveries are expected, 3PL can help you meet and exceed customer expectations, potentially leading to increased loyalty and repeat business.

Evolution of 3PL

The journey of 3PL services is a testament to how rapidly business needs have changed over the past few decades. Understanding this evolution will help you see why 3PL has become so essential today.

- Early days: 3PL emerged in the 1970s and 1980s. Initially, it focused primarily on transportation and warehousing. Companies would outsource these basic functions to reduce costs and simplify operations.

- Expansion of services: As businesses grew more complex in the 1990s, so did 3PL offerings. Providers began to offer more comprehensive services, including inventory management, packaging, and order fulfillment.

- Globalization era: The 2000s saw rapid globalization. 3PL providers expanded their networks internationally, offering businesses the ability to reach global markets without setting up their own overseas operations.

- Technology integration: The rise of e-commerce in the late 2000s and early 2010s pushed 3PL providers to adopt advanced technologies. Real-time tracking, automated warehousing, and sophisticated inventory management systems became standard offerings.

- Omnichannel support: As retail shifted towards an omnichannel approach, 3PL providers adapted to support both online and offline sales channels. This meant developing capabilities for everything from individual order fulfillment to bulk store replenishment.

6 Key Trends Transforming the 3PL Industry

While progress in the logistics industry started off slowly, today’s technological advancements are moving at a rapid pace. Let's take a look at how it's revolutionizing the 3PL sector.

1. Automation in Warehouse Operations

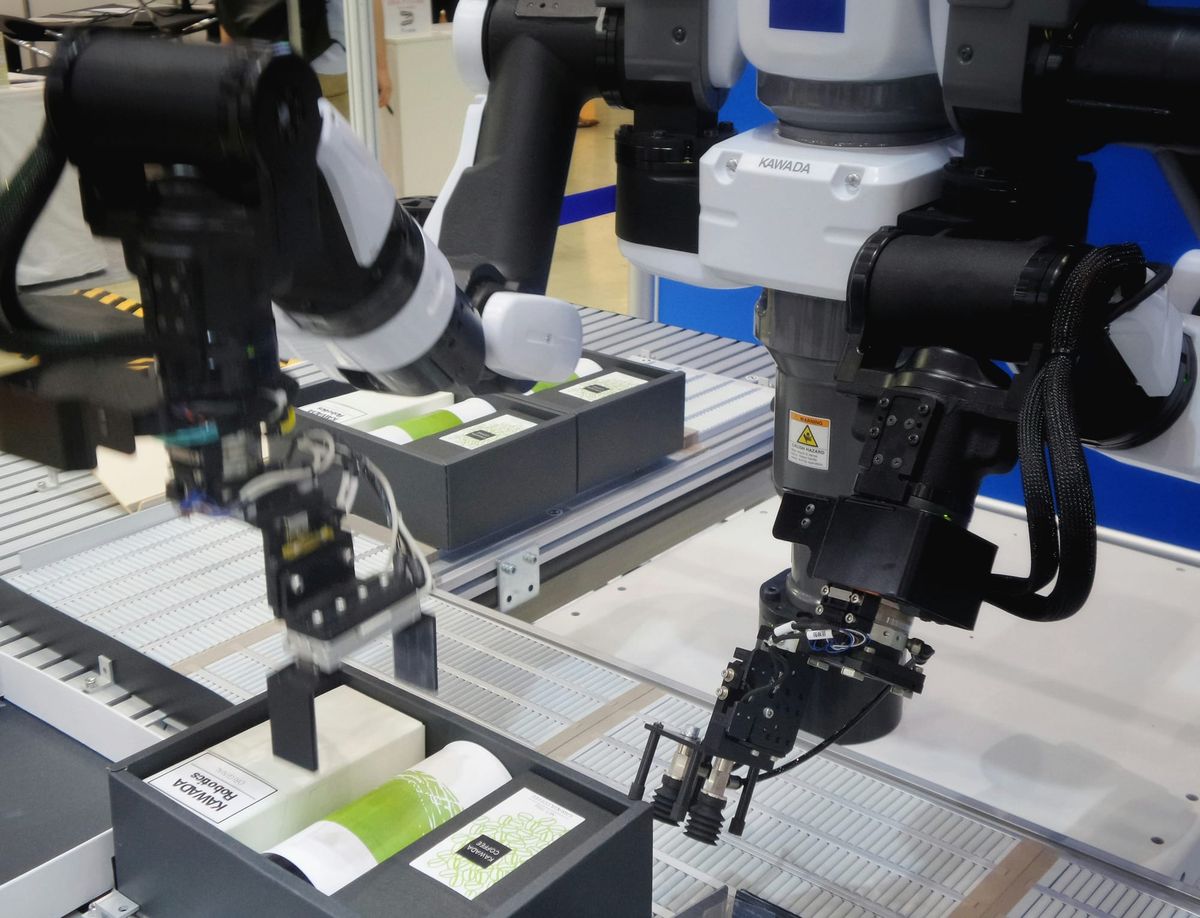

Automation is reshaping how third-party logistics (3PL) providers manage their warehouses and distribution centers, driving efficiency, accuracy, and speed in order fulfillment. By the end of 2024, around 50% of logistics companies aim to automate their warehouses using robots. Plus, over 65% of AI tools are expected to integrate seamlessly with IoT devices and sensors, improving operational coordination.

Here’s how various automation technologies are enhancing 3PL operations:

- Robotic Process Automation (RPA): Changing the game in picking, packing, and sorting, RPA uses robots to retrieve items from shelves, pack boxes with precision, and quickly route packages to the correct shipping areas, reducing human error and speeding up processes.

- Automated Guided Vehicles (AGVs): These self-driving vehicles transport pallets and bins within warehouses, operating continuously to cut labor costs and boost efficiency. Equipped with sensors, AGVs also enhance safety by preventing collisions.

- Autonomous Mobile Robots (AMRs): Unlike AGVs, AMRs dynamically plan their routes using AI and advanced sensors. They assist in order fulfillment alongside human workers and can be reprogrammed to meet changing needs, offering unmatched flexibility.

- Automated Storage and Retrieval Systems (AS/RS): Utilizing cranes and shuttles, these systems optimize warehouse space by storing and retrieving goods in high-density setups, ideal for environments like cold storage that challenge human capabilities.

- Conveyor and Sortation Systems: Continuously evolving, modern conveyor and sortation systems integrate with management software for real-time tracking, handling diverse package sizes and weights to streamline the flow of goods.

- Drones for Inventory Management: Although still emerging, drones are proving valuable for counting inventory in hard-to-reach areas, locating items quickly with their cameras and scanners to improve inventory accuracy and reduce search times.

2. Predictive Analytics and Demand Forecasting

Predictive analytics are transforming how third-party logistics (3PL) providers manage operations by making inventory management more precise and enhancing responsiveness to market dynamics. This approach includes:

- Inventory Optimization: By using historical data and analyzing patterns, 3PL providers can keep inventory at optimal levels, avoiding overstock and shortages.

- Responsive Demand Sensing: Real-time data enables 3PLs to quickly respond to demand changes, adjusting logistics strategies to maintain efficiency and competitiveness.

- Accurate Seasonal Planning: Advanced forecasting tools predict seasonal trends, allowing for strategic resource allocation and readiness.

- Proactive Risk Management: By predicting potential disruptions from various sources, 3PLs can create effective contingency strategies, enhancing supply chain resilience.

- Efficient Transportation: Analyzing routes and delivery data helps optimize logistics, ensuring faster and cost-effective deliveries with predictive maintenance to avoid delays.

3. Sustainability and Green Logistics

As environmental concerns grow, the logistics industry is responding with sustainable practices aimed at reducing its ecological footprint.

A recent study shows that one-third of consumers are ready to pay more for sustainable products, indicating that businesses should anticipate sustainability becoming the norm rather than the exception in the future.

Dr. Andreas von der Gathen, co-CEO of Simon-Kucher said:

“The relative importance of sustainability during the purchase process will continue to increase. Today, 50 percent of consumers rank sustainability as a top five value driver…As expectations around sustainability climb, companies will face significant pressure to prove their sustainability credentials and continue to make it a central part of their value proposition.”

Here's how 3PL providers are driving these changes:

- Eco-Friendly Transportation: 3PLs are increasingly using electric (EVs) and hybrid vehicles for last-mile deliveries and exploring alternative fuels like biodiesel and hydrogen for longer routes. Route optimization software also plays a crucial role in reducing emissions by ensuring the most efficient transport paths.

- Sustainable Packaging Solutions: 3PLs are using recycled materials, optimizing packaging sizes, and exploring biodegradable options to reduce waste and potentially lower shipping costs.

- Energy-Efficient Warehousing: Modern warehouses are being designed with sustainability in mind, utilizing LED lighting, solar panels, and advanced insulation to minimize energy use. Some warehouses even achieve net-zero energy status.

- Reverse Logistics and the Circular Economy: 3PLs enhance reverse logistics to manage returns more efficiently, helping to refurbish and recycle products, which is particularly important in e-commerce to reduce waste and enhance customer satisfaction.

- Carbon Footprint Tracking and Reporting: Many 3PLs now provide services to track and report the carbon footprint of logistics activities, enhancing transparency for regulatory compliance and corporate social responsibility. Some also offer carbon offset programs to help balance out emissions.

4. E-Commerce and Omnichannel Fulfillment

The surge in e-commerce and the shift towards omnichannel retail strategies are transforming how providers offer their services to meet dynamic consumer needs.

- Integration of Online and Offline Channels: 3PL providers are creating sophisticated inventory management systems that ensure seamless integration across all sales channels. This not only facilitates options like buy online, pick up in-store (BOPIS) and ship-from-store to enhance customer convenience and reduce delivery times, but also allows for flexible inventory sourcing to better meet consumer demands.

- Last-Mile Delivery Innovations: To address consumers' expectations for quick and convenient delivery, 3PLs are partnering with local couriers and exploring innovative delivery methods such as autonomous vehicles and drones. Additionally, they are developing networks of parcel lockers and collaborating with retail locations to create accessible customer pickup points.

- Reverse Logistics and Returns Management: Given the higher return rates in e-commerce, 3PLs are focusing on efficient reverse logistics by establishing specialized return centers and employing technology to streamline the returns process. These improvements include instant refunds, easy return label generation, and using AI to analyze return patterns to enhance product quality and customer satisfaction.

- Fulfillment Center Networks: To ensure rapid delivery times, 3PLs are diversifying their fulfillment networks. By setting up smaller, strategically located centers near major population areas, they can deliver quickly and cost-effectively, enabling competition with large e-commerce entities without heavy infrastructure investments.

- Value-Added Services: 3PLs are expanding their services to cater to unique e-commerce needs, including kitting, custom packaging, and product customization prior to shipping. They also provide specialized handling for certain product types, such as apparel and electronics, enhancing product care and customer experience.

5. Data-Driven Logistics and Big Data

Big data refers to the massive amounts of data generated by various sources, including sensors, social media, and customer interactions. The logistics sector is undergoing a data-driven revolution, enabling 3PL providers to improve decision-making and optimize their operations through real-time insights and analytics.

Key components include:

- Enhanced Real-Time Visibility: IoT devices and advanced tracking systems provide complete transparency across the supply chain, enabling immediate adjustments to operations and improving customer satisfaction with up-to-date delivery information.

- Intelligent Routing and Network Optimization: Big data analytics improve the planning and execution of transport routes by considering traffic, weather, and historical data, which enhances the efficiency and sustainability of shipping operations.

- Advanced Performance Metrics: Detailed analytics on performance indicators such as delivery timeliness, inventory accuracy, and fulfillment rates help monitor effectiveness and pinpoint improvement areas, supported by customizable dashboards for real-time analysis.

- Deeper Customer Insights: Data on customer behavior, such as purchase patterns and demand spikes, informs better inventory and marketing strategies, aligning product offerings with customer needs.

- Rigorous Security and Compliance: As reliance on data increases, so does the emphasis on cybersecurity and regulatory compliance, ensuring the protection of sensitive information and adherence to industry standards.

6. The Rise of 4PL and Beyond

As supply chains become increasingly complex, a new model of logistics management is emerging: Fourth-Party Logistics (4PL). Unlike 3PL providers who focus on specific logistics functions like warehousing or transportation, 4PL providers manage the entire supply chain. They serve as a single point of contact, coordinating with multiple 3PLs, carriers, and other service providers.

Here's what 4PLs offer:

- Strategic Partnership and Consultation: 4PL providers serve as strategic partners, offering consultation to align logistics operations with your overall business goals. This may include redesigning the supply chain, advising on tech investments, or creating plans for potential disruptions, aiming to improve customer service, agility, and risk management.

- Technology Integration: 4PLs integrate various advanced software platforms that enhance visibility and control over the entire supply chain. These systems allow for real-time decision-making and streamlined operations through a single interface, managing multiple logistics functions and providers.

- Flexibility and Scalability: The 4PL model is highly adaptable, quickly adjusting to changes in your business needs. This flexibility is crucial for businesses experiencing growth or entering new markets, helping navigate complex logistics without extensive in-house capabilities.

- Continuous Improvement and Innovation: 4PLs are at the forefront of logistics innovation, continuously exploring new technologies and methods to improve supply chain performance. This partnership allows you to leverage these advancements without the direct cost, maintaining a competitive and efficient supply chain.

The following table presents a quick comparison of 1PL, 3PL, and 4PL logistics providers.

| Description | Responsibilities | Key Characteristics | |

|---|---|---|---|

| 1PL | First-Party Logistics | Typically, the manufacturer or retailer who manages their own logistics. | Direct control of all logistics operations without outsourcing. |

| 2PL | Third-Party Logistics | Outsourced providers that handle storage, transportation, and distribution logistics. | Specialized in logistics management, provides operational relief and expertise. |

| 3PL | Fourth-Party Logistics | Manages entire supply chains, overseeing 3PLs and other supply chain elements. | Offers strategic insight, integrates technology, and manages comprehensive supply chain solutions. |

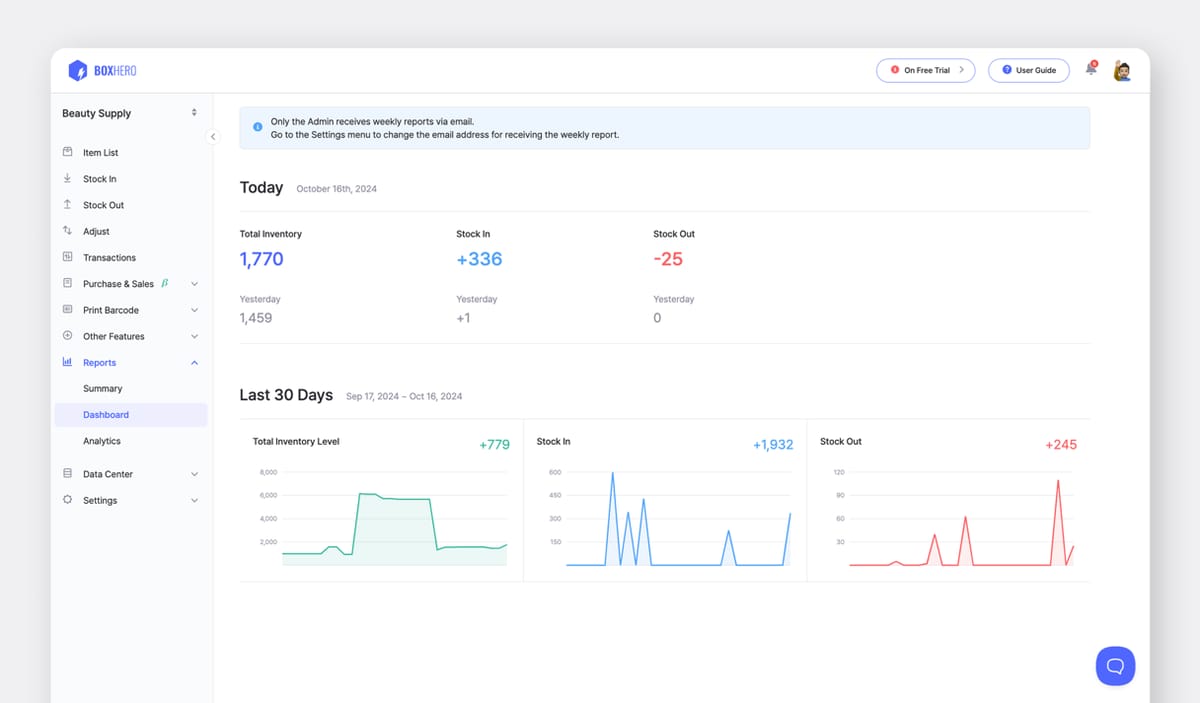

Optimizing 3PL Performance with BoxHero

As technology plays an ever-growing role in the competitive 3PL industry, BoxHero's inventory management solution is essential for providers looking to meet evolving client needs.

- Multi-Client Stock Management: BoxHero excels in managing inventories for multiple clients within one system. This feature is particularly useful for 3PL providers managing diverse product lines, ensuring accurate inventory tracking and reporting for each client. It aligns with the shift towards integrated, 4PL-style services, offering comprehensive inventory management.

- Real-Time Visibility Across Warehouses: BoxHero offers real-time tracking across multiple warehouses, enhancing supply chain visibility. This is essential for businesses implementing omnichannel strategies or managing complex supply chains, providing the necessary data to make informed decisions and maintain optimal inventory levels.

- Low Stock Alerts and Demand Forecasting: The system’s low stock alerts prevent stockout. Customizable reorder points allow 3PL providers to proactively manage inventories, enhancing product availability and customer satisfaction. This feature supports the trend towards data-driven decision-making.

- Barcode Scanning for Improved Accuracy: BoxHero’s barcode scanning increases accuracy and efficiency in inventory counting and order fulfillment. It reduces errors, speeds up service, and lowers costs, improving overall customer satisfaction for 3PL clients.

- Analytics for Informed Decision Making: With tools that offer insights into inventory performance and turnover rates, BoxHero enables 3PL providers to become strategic partners, offering recommendations for inventory optimization and detailed performance reporting.

- Cloud-Based Solution for Flexibility and Scalability: As a cloud-based platform, BoxHero provides the necessary flexibility and scalability for modern 3PL operations. It facilitates easy access from various locations, accommodates remote work, and adjusts to business needs across various industries.

Enhancing Efficiency in Logistics Management

The logistics sector is continuously evolving, requiring ongoing updates in technology and strategies to maintain competitive advantage and efficiency. This transformation involves adopting sustainable practices and advanced technologies such as AI and IoT to tackle modern challenges.

For 3PL providers looking to adapt and succeed in this landscape, tools like BoxHero provide essential support. By using BoxHero's inventory management capabilities, your operations can stay efficient, resilient, and well-prepared for future demands.