Is Your Inventory Ready for the Holidays? 9 Key Tips for a Busy Season

Thanksgiving, Christmas, New Year—the holiday season can sneak up on you. One minute, you're ordering your regular stock, and the next, you're scrambling to keep up with the December rush. If you've ever run out of a popular item mid-season or found yourself buried in excess inventory come January, you know the importance of getting your inventory right.

According to the National Retail Federation and Prosper Insights & Analytics, average consumer spending for the winter holidays is projected to reach a record $902 per person, which is $25 more than last year.

“The winter holidays are a treasured time for Americans, and they are prioritizing spending on family this holiday season. Despite the shorter window of time between Thanksgiving and Christmas, retailers are prepared to meet the needs of consumers by providing holiday shoppers with earlier deals and sales and by ensuring inventory is available for the most in-demand items this year.”

- Katherine Cullen, VP of Industry and Consumer Insights at NRF

That's great news for your business—if you're prepared. But being prepared doesn't mean ordering everything in sight or hoping last year's strategy will work again.

In this guide, you'll find practical tips to help you:

- Order the right amounts at the right time

- Keep your best-sellers in stock

- Handle the surge in orders

- Manage returns after the holidays

- Use your data to make smart decisions

Whether you're gearing up for your first holiday season or looking to improve on last year's performance, these tips will help you stay organized and keep your shelves stocked with what customers want. Effective use of inventory management software, such as BoxHero, can enhance these strategies, providing the tools you need to succeed.

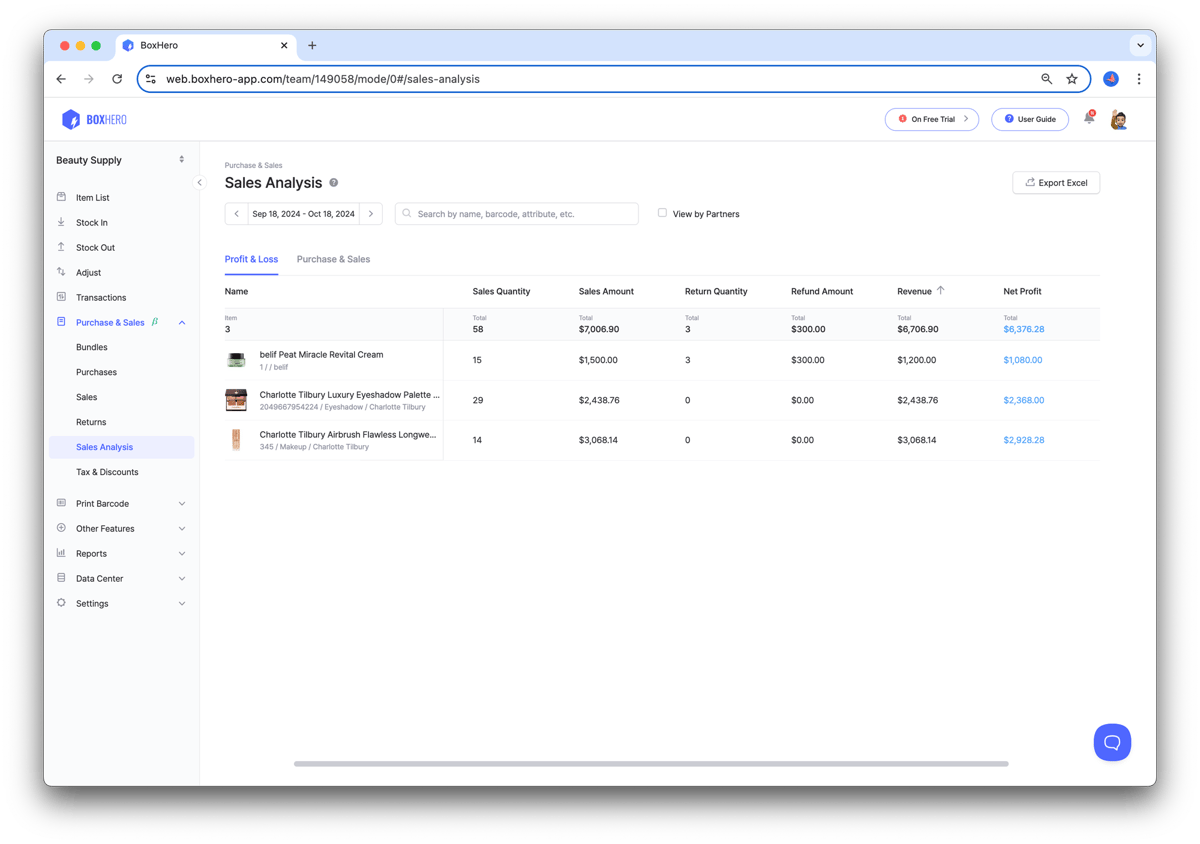

Tip #1: Start with Last Year's Numbers

Your past sales (historical data) hold valuable clues for this year's planning. Open up last year's holiday records and look for the patterns that matter: Which items sold out first? What sat on your shelves too long? When did your busiest days hit?

Here's what to focus on:

- Peak selling periods (Early December? The week before Christmas?)

- Your top 5-10 products by sales volume

- Items that sold out unexpectedly

- Inventory that moved slower than expected

For example, if your scented candles flew off the shelves by December 10th last year while some gift baskets lingered until January, you'll want to adjust those numbers accordingly this year.

Tip #2: Order Smart, Order Early

If there's one thing that can throw off your holiday plans, it's late stock arrivals. Getting your orders in early isn't just about beating the rush—it's about giving yourself room to maneuver when things don't go as planned.

Start placing your holiday orders now. Many suppliers get backed up by October, and shipping times often double during peak season. Plus, ordering early often means better prices and first pick on popular items.

A practical approach to holiday ordering:

- Split your orders: Order 60% now, 20% in a few weeks, and keep 20% flexible

- Order extra of your proven bestsellers

- Consider storage space—can you handle all orders arriving at once?

- Keep some budget in reserve for rush orders if needed

Pay attention to items with longer lead times. Those custom gift items or products from overseas? They should be at the top of your order list.

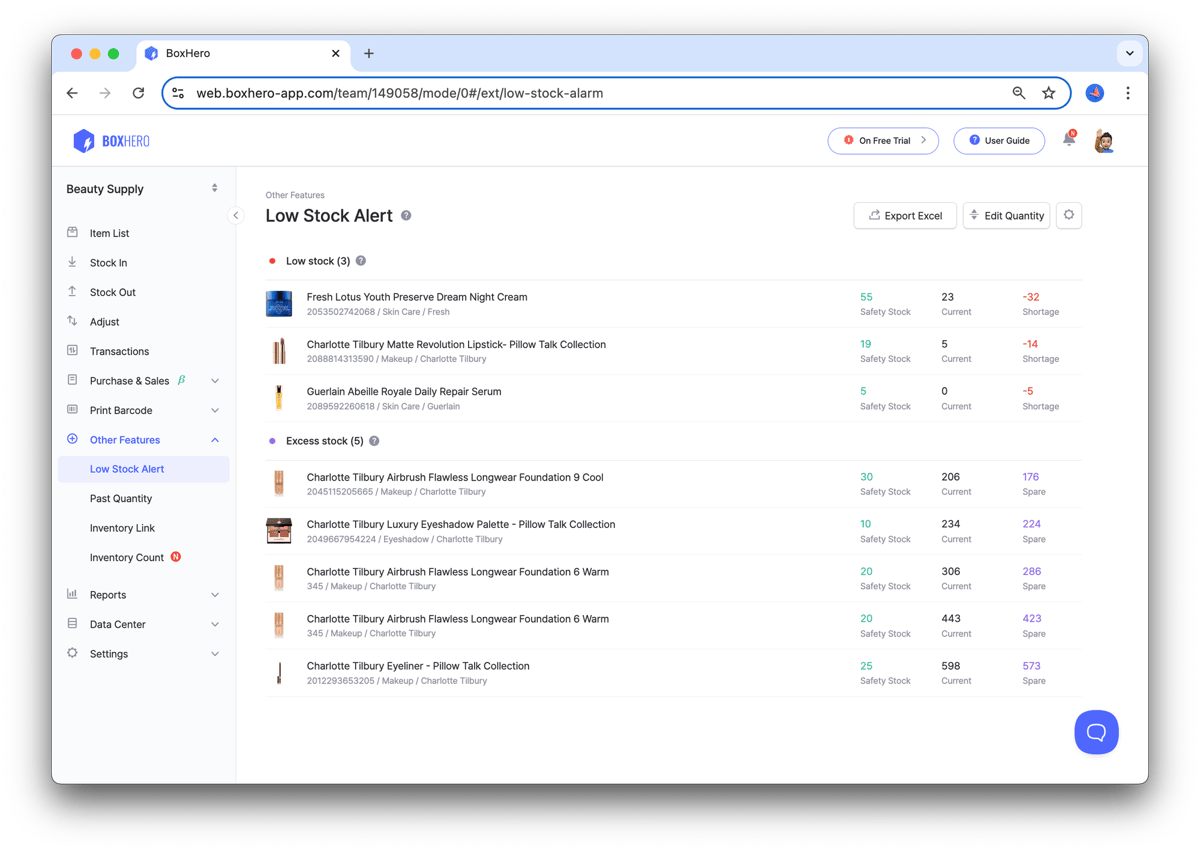

Tip #3: Set Smart Stock Alerts - No More Stockouts

According to a McKinsey report, around 60% of consumers faced out-of-stock products during the 2021 holiday season; out of those, 70% switched brands.

Running out of stock in December isn't just frustrating—it's expensive. Smart stock alerts help you stay ahead of inventory gaps, especially during those unexpectedly busy days when regular monitoring isn't enough.

Start by reviewing your minimum stock levels. What worked in September probably won't cut it for December. For holiday bestsellers, consider doubling your usual minimum thresholds.

Here's how to set effective stock alerts:

- Identify your can't-run-out items—these need the highest alert levels

- Add buffer time for reorders during busy periods

- Set different thresholds for different product categories

For example, if gift sets take two weeks to restock, set alerts when you still have three weeks of inventory left. For quick-turnaround items like gift wraps or cards, a week's notice might be plenty.

Tip #4: Make Your Space Work Harder

A well-organized warehouse isn't just about finding things quickly—it's about keeping your team moving efficiently when orders start flooding in. The best time to optimize your space is before the holiday rush hits.

Start with your bestsellers. Place these items in easy-reach locations near packing stations. Think about product weight, too—keep heavy items at waist level to prevent strain during busy periods.

Create dedicated zones for:

- New arrivals

- Popular gift combinations

- Returns processing

- Ready-to-ship orders

Small changes make a big difference in December. Add clear labels that are visible from all angles. Mark aisles and shelves with large, readable numbers. Use color coding if it helps your team work faster.

Need more space? Look up. Most storage areas have unused vertical space. Adding another shelf level might give you the extra capacity you need for holiday inventory.

Keep some flexibility in your layout—you may need to adjust it as certain items become unexpected holiday favorites. A good rule of thumb: leave 20% of your space adaptable for last-minute changes.

Tip #5: Get Ready for the Return Wave

January's return season can be just as busy as December's sales rush. Smart preparation now means fewer headaches later. The post-holiday period often brings in 30% more returns than usual months, making a solid returns system essential.

Set up a dedicated returns station. You'll need clear space for incoming packages, quality check area, and repackaging supplies.

Speed matters with returns. The faster you process them, the sooner items can go back into available stock. Create a simple checklist for your team:

- Log the return reason

- Check item condition

- Update inventory status

- Process refund or exchange

- Return to stock or mark for disposal

Some items need special attention. Opened electronics might need testing. Clothing requires inspection. Build these quality checks into your process before the rush starts.

Tip #6: Train Your Team Early

A well-trained team is your best asset during the holiday rush. When orders are pouring in, you need everyone working confidently and independently.

Start with the basics. Run practice sessions using your inventory system with real scenarios:

- Processing multiple orders at once

- Handling split shipments

- Managing returns

- Finding alternate items when something's out of stock

Document your processes clearly. Write down steps for common tasks and post them where they're easy to see. Include photos if helpful—a picture of a properly packed box can prevent mistakes better than a paragraph of instructions.

Take time now to answer questions. It's much harder to explain procedures when you're in the middle of holiday crowds.

Share last year's experiences. If you've been through a holiday season before, tell your team what to expect. For instance, which days were busiest, common customer questions, typical challenges, and what worked well in the past.

Tip #7: Build Your Safety Net

Even perfect planning can't prevent every problem. Having backup plans ready keeps small issues from becoming major disruptions during peak season.

Know your backup suppliers. Build relationships with alternate vendors now—you won't have time to research options when you're running low on a popular item. Keep a list of:

- Which suppliers carry your essential items

- Their typical lead times

- Minimum order requirements

- Contact information for key people

Keep extra shipping supplies on hand. Running out of boxes or packing materials can halt operations as quickly as running out of stock. Add 25% to your normal holiday estimates for supplies.

Plan for adequate staff coverage. Illness or personal emergencies don't take a holiday break. Have contact information ready for temporary help, or consider cross-training current team members to cover key roles.

Don't hesitate to ask for help and involve 3PL providers: 3PL providers have established, efficient logistics networks. By leveraging their resources, you can reduce the time it takes to ship products to your customers. Select a 3PL provider that aligns with your business needs and values. Consider factors such as their track record, technology, scalability, and their ability to handle peak season volumes.

Tip #8: Watch and Respond to Early Signals

The first weeks of holiday shopping tell you a lot about what's ahead. Pay attention to early patterns—they often predict your whole season.

Watch your numbers daily. Quick responses to sales trends can make the difference between a good season and a great one. Check:

- Which items are moving faster than expected

- What customers are asking about

- How accurate your initial stock estimates were

Don't wait for items to sell out before taking action. If a product is selling 20% faster than predicted, place reorders now. Early restocking gives you options—last-minute orders often mean paying premium prices or settling for substitutes.

Look for unusual patterns. If a typically slow-moving item starts selling quickly, there's usually a reason. Check social media or ask customers what's driving their interest—this insight helps with reorder decisions.

Bonus Tip: Put Technology to Work

Time spent setting up good tools pays off when holiday orders start rolling in. The right system turns complex inventory tasks into simple ones.

Good inventory software should:

- Track products across multiple locations

- Send alerts before you run out of stock

- Process orders quickly

- Generate clear reports

- Work well on mobile devices

The best part about modern inventory tools? They catch human errors before they become problems. No more miscounts during busy days or forgotten reorders during rush periods.

Wrapping Up: Stay Prepared, Stay Ahead

The holiday rush brings both opportunity and challenge. Good preparation makes the difference between struggling through the season and sailing through it smoothly.

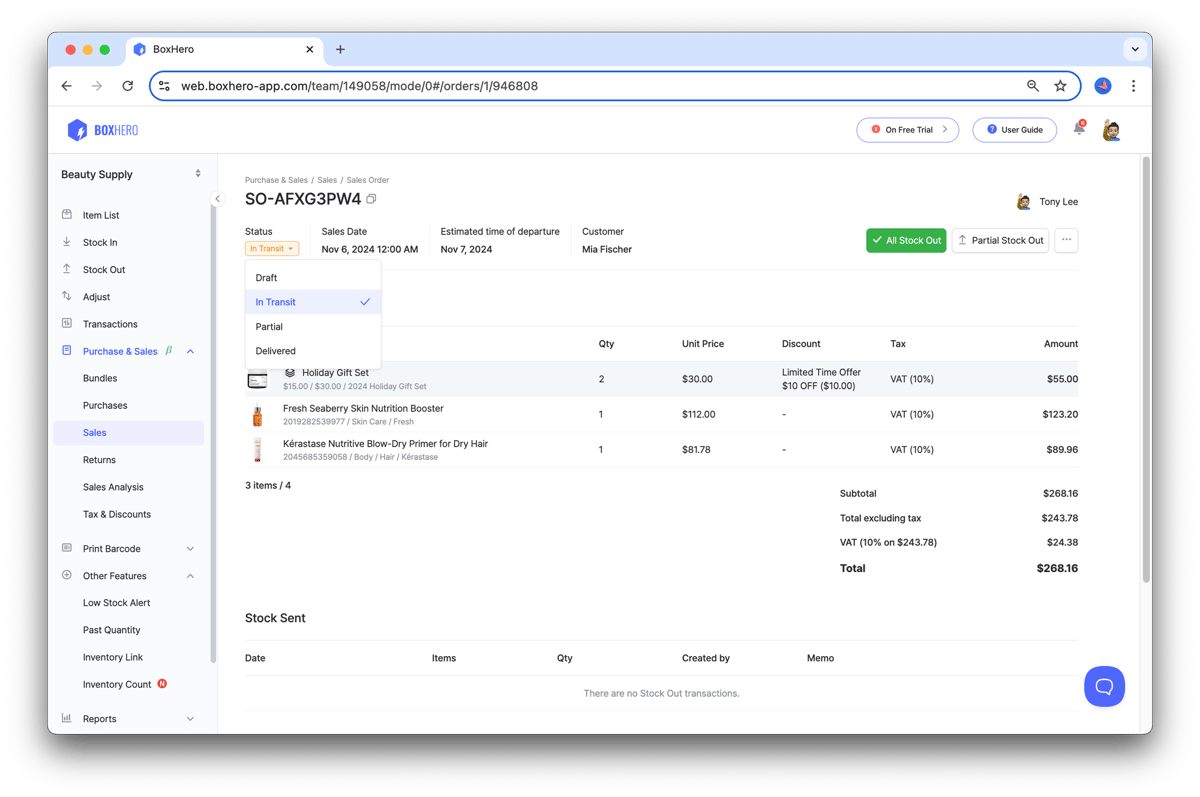

Maintain a balanced inventory, strengthen supplier relationships, and use technology to enhance operations. Watch early trends and keep your backup ready. Ultimately, every element of your inventory management plan should improve customer satisfaction.

With the right systems and planning in place, you can focus on serving customers instead of fighting inventory fires. Boxhero helps you handle purchases, sales, and returns efficiently, avoid stockouts with low stock alerts, and make smarter decisions with powerful analytics.

Avoid inventory headaches and let BoxHero streamline your inventory management so you can devote more time to delighting your customers.