How Much Inventory Should I Have? Answers for Newbies and Shops With Sales History

Instead of giving you a magic number, we’ll share a flexible framework to help you decide what’s right for your business.

Do you plan your meals and grocery shop in advance? Or are you part of the 52% of consumers who say that “ordering takeout from a restaurant is an essential part of their lifestyle”? 🙂

There’s a good reason why so many people prefer dining out or getting food delivered over cooking at home. Meal planning is hard—especially for big families with different preferences, a fridge full of expiry dates, and the chaos of everyday life.

It just goes to show how tough planning ahead can be, and inventory planning for owners of small businesses is no different.

Order too little, and you risk running out of stock just when demand picks up. On top of that, having to go through the whole ordering process all over again isn’t much fun.

When you're trying to figure out how much inventory to keep on hand, there’s no simple answer, because it doesn’t exist.

That’s why instead of giving you a magic number, we’ll share a flexible framework to help you decide what’s right for your store. Whether you're just starting out or already have a few sales under your belt, this guide will meet you where you are.

We’ve broken things down into two key sections:

- Part 1: For new entrepreneurs with no sales history

- Part 2: For store owners with existing data to work with

Part 1: No Sales History? Here’s How Much Inventory to Carry

Starting a store from scratch is exciting, but also risky.

Unlike digital products or services, selling physical goods means upfront investment. You have to purchase inventory before you’ve made a single sale. That’s a big commitment, especially when you don’t have past data to lean on.

So how do you approach inventory planning with no sales history?

▶︎ Borrow insights from those who’ve done it before.

▶︎ Treat your first inventory like a prototype.

Tip #1: Borrow Insights From Those Who’ve Done It Before

Let’s say you’re selling handmade candles. Your inventory needs will look nothing like someone running a boutique clothing store. The products, price points, and customer behavior are all different.

So what do you do?

The quickest way to get practical, experience-based advice is to tap into the collective knowledge of other entrepreneurs in your niche.

One of the best (and cheapest) ways to do this is through online communities.

YouTube is overflowing with content like “How I launched my Etsy shop” or “Starting a T-shirt brand from scratch”. Many of these videos come from people who’ve faced the exact same questions you’re asking. You’ll find honest takes on what worked, and what didn’t.

Reddit is another goldmine. The r/Etsy subreddit alone has over 250,000 members sharing tips, questions, and real-life examples of what inventory levels worked for them.

Of course, always approach online advice with a healthy dose of skepticism. What worked for someone else may not apply exactly to you, but it can be a starting point to test and learn from. Sometimes, you really don’t have to reinvent the wheel.

Tip #2: Use the “Minimum Viable Inventory” Approach

Starting a store is a lot like launching a startup: you're creating something new, learning what works, and figuring out where your product fits.

There’s a useful idea from the startup world called the Minimum Viable Product (MVP). It’s the simplest version of a product that’s just good enough to test your idea and get feedback.

You can apply that same logic to inventory. Think of your first set of products as your Minimum Viable Inventory.

It’s not about stocking up—it’s about testing, learning, and adjusting. Your goal isn’t to hit a big sales number or build a loyal customer base from the start. It’s figuring out what works:

• Can you replicate that sale?

• What does it tell you about your product, pricing, or messaging?

When you start small, you’re not just protecting your budget. You’re buying insight. So when someone asks, “How much inventory should I start with?” the honest answer is:

Just enough to test your ideas and see what people actually want.

Part 2: Already Have a Store? Let Your Sales Data Guide You

Once your store is up and running, inventory planning becomes less about guesswork and more about strategy. And spreadsheets.

On the plus side, you now have a history of sales, which tells you what’s selling well, and when. But on the flip side, managing inventory becomes more complex. You’re no longer working off instinct or online advice alone; you need to track real data and make decisions based on it. This is the point where you’d better start loving those STEM disciplines. 🙂

So how do you make sure you’re ordering the right amount of stock—not too much, not too little?

Tip #1: Track Your Sales Numbers for Insights

Let’s look at one powerful metric: Days Inventory Outstanding (DIO).

DIO tells you the average number of days it takes to sell the inventory you have on hand, based on past performance.

Think of it like this: if you walk into your warehouse today, how long would it take to sell everything sitting there? That’s exactly what DIO helps answer.

Here is the formula for calculating DIO:

Let’s break it down:

- Pick a time period. This could be a year, a quarter, or a month. Choose one where you have both sales and inventory data.

- Calculate your average inventory during that period. Add the inventory value at the start and end of the period, then divide by two.

- Calculate your COGS (Cost of Goods Sold) for the same period. This is the total cost of the products you actually sold in that time.

- Multiply by the number of days in the period. For example, use 365 for a full year.

Let’s say we look at Costco’s 2024 numbers (from their annual report):

• Inventory value at the start of the year: $16.6B

• COGS: $222.4B

Now plug those into the formula:

DIO = 28.9 days

This means that on average, Costco keeps about a month’s worth of inventory on hand at any given time.

Knowing your DIO gives you more than just a number. It helps you anticipate challenges and stay prepared for stockouts, slow-moving inventory, and potential changes in demand.

Let’s say your DIO is around 29 days, like Costco’s. That tells you:

• You’ll need enough time to order, receive, and stock new inventory on your shelves before running out.

• Your entire operations, including ordering, shipping, and product stock-in, need to work on the same monthly rhythm.

DIO is just one of many industry KPIs that inventory managers use to plan their purchases. If you want to dig into other useful metrics, like turnover rate or inventory value, we’ve got you covered.

Check out our full breakdown of key supply chain KPIs. It’s a great next step if you’re ready to get more hands-on with your numbers.

Tip #2: Factor In Your Supplier Lead Time

Supplier lead time refers to how long it takes for your suppliers to deliver products once you’ve placed an order.

Say you notice that those red dresses are flying off your shelves. Customers love them, and they’re telling their friends and family to get one too. You want to restock quickly to ride the wave of demand.

But here’s the catch: how long will it take your supplier to fulfill that new order?

Understanding lead time helps you plan for moments like this. Even better, consistent delivery times allow you to measure and automate parts of your inventory ordering process.

One smart move is to establish a reorder point, also known as safety stock. This is the inventory level at which you should place a new order to avoid running out. Here is the formula:

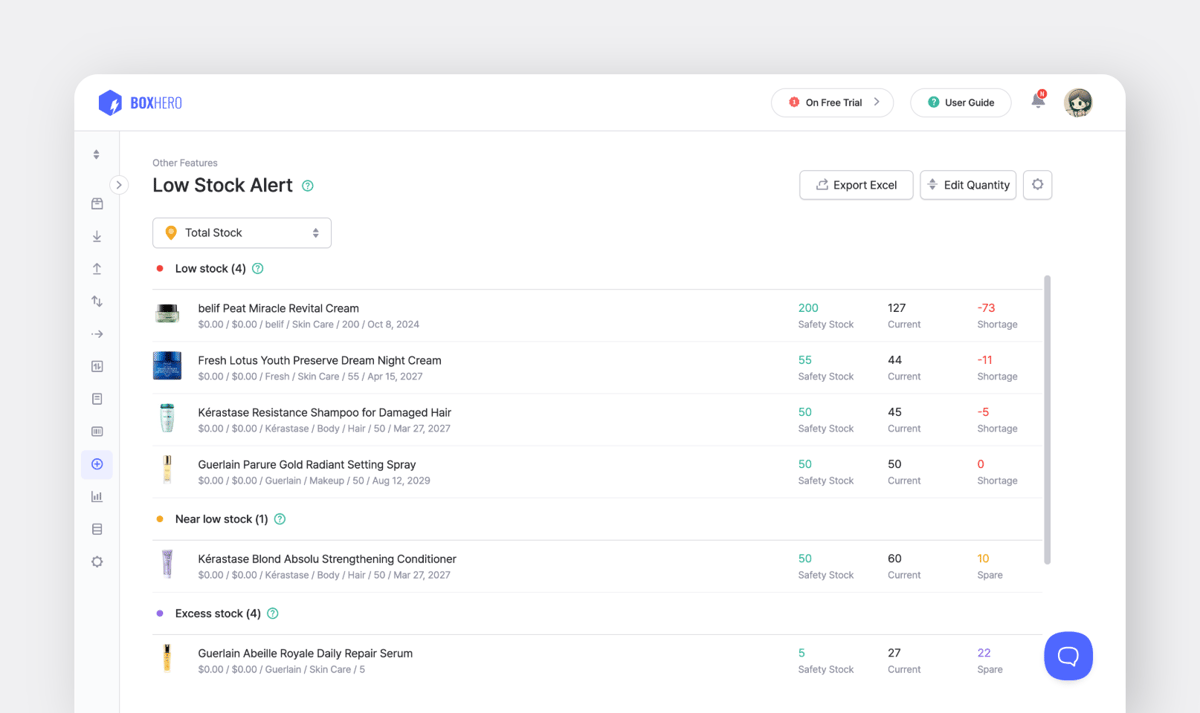

If you’re using BoxHero, follow these steps to automate your stock control and avoid stockouts:

- Calculate the supplier lead time for a given product.

- Multiply your expected daily sales by the lead time to determine the reorder point.

- Enter that reorder point as the “Safety Stock” level for that product in BoxHero.

- Set up notifications to alert you whenever the product quantity falls below that threshold.

- Sit back in your chair and relax. You’ve got one less thing to track and some additional time for more enjoyable tasks.

Sign up for a free 30-day trial of BoxHero, or request a product demo.

Tip #3: Consider Cash Flow Limitations

For any business, having enough funds to cover day-to-day operations is a key indicator of financial health.

When you invest heavily in inventory, you reduce the cash available for other essential needs such as salaries, taxes, paid advertising, or consulting services. That’s why, even if your products don’t have specific expiry dates, putting all your money into stock “just in case” is rarely a smart inventory strategy. Unless you’re confident in the demand, you could be sitting on dead stock and limited liquidity.

Instead, align your inventory planning with your cash flow. If your sales tend to spike seasonally, try to time larger purchases during periods of strong revenue.

For more insights and practical recommendations on managing working capital efficiently, check out the article below:

Conclusion

If you’ve been putting off launching or scaling your retail business because inventory feels too complex, here are a few ideas to help you move forward:

- If you don’t have a sales history to base your decisions on, look for insights from others in your product niche who’ve done it before. Explore online communities of retail founders on YouTube or Reddit for firsthand stories and practical advice.

- Treat your initial inventory purchases as an investment in learning and gathering feedback from real customers.

- Learn how to extract value from spreadsheets and numbers. Simple metrics to start with include DIO (Days Inventory Outstanding), supplier lead time, and reorder point (safety stock). Numbers become even more important for maintaining a healthy cash flow between inventory purchase and its liquidation.

- Rely on automation from inventory management platforms like BoxHero to simplify the process.

Start small, stay curious, and with the right approach, you can grow confidently without letting inventory hold you back.