Inventory Management 101: The Backbone of a Successful Business

Inventory management might not sound like the most exciting aspect of business operations, but it undoubtedly stands as one of the most crucial. Whether you're a retail giant with multiple outlets or a small online startup, understanding the basics of inventory management can be the difference between profit and loss.

In this article, we delve into the essentials of inventory management and why it's paramount to the success of any business.

Key Takeaways:

Importance of Inventory Management: Efficient inventory management is crucial for maintaining positive cash flow, meeting customer demand, reducing associated storage and holding costs, and directly enhancing business profitability.

Essential Components for Effective Management: Several foundational components drive effective inventory management. These include practices like Stock Review, ABC Analysis, understanding MOQ and EOQ, the FIFO principle, and maintaining Safety Stock.

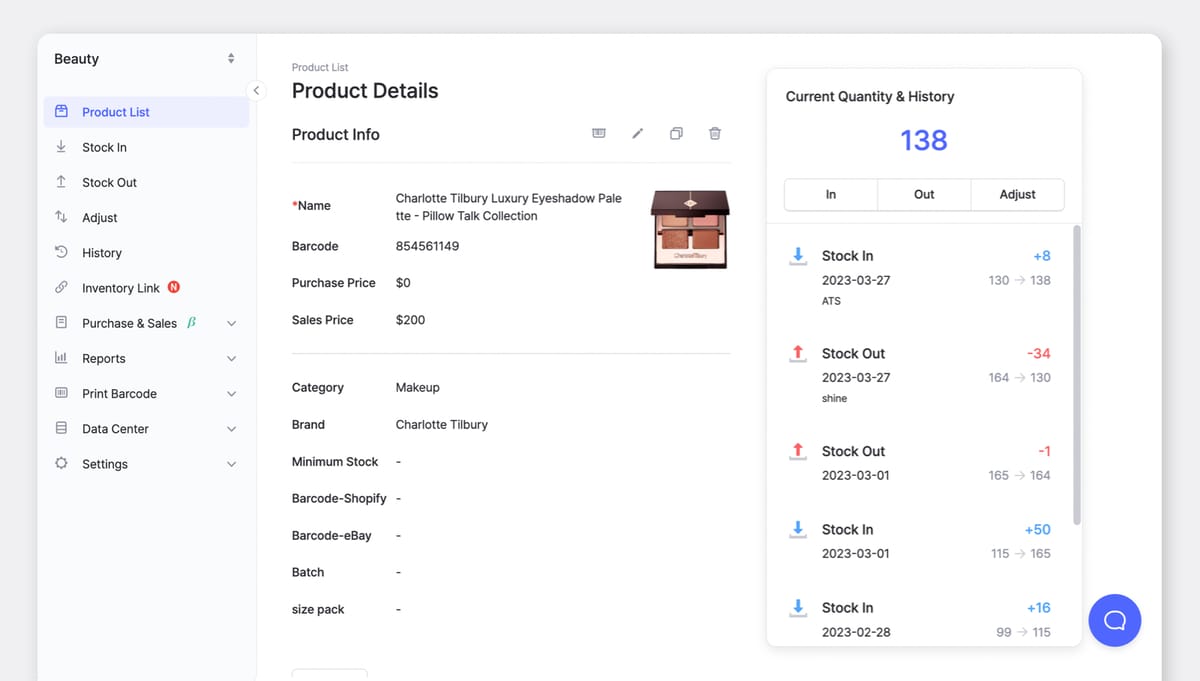

Technological Integration: Modern inventory management often relies on technological tools and software solutions, such as BoxHero, SAP Business One, and Oracle NetSuite. These platforms provide real-time tracking, analytics, and forecasting, optimizing inventory processes and ensuring business efficiency.

What is Inventory Management?

At its core, inventory management revolves around overseeing and controlling the ordering, storage, and use of a company's inventory. This includes the management of raw materials, components, and finished products, as well as warehousing and processing of such items.

For most retailers and online sellers, inventory means finished products that are stored in a warehouse ready to be sold online or in-store. To effectively manage inventory means that the products that you own are shipped out frequently and replenished appropriately to compensate for customers' continuous demand.

Why is Inventory Management Important?

Cash Flow

Inventory is money sitting on shelves or in warehouses. Efficient inventory management ensures that you're not investing more than required in products or materials, aiding in maintaining positive cash flow.

Cash flow is the lifeblood of continuing business operations. Because inventory is tied-up cash, businesses have to make sure that there isn't too much of it.

Meeting Demand

One of the worst situations for a retailer is to run out of stock when there's demand. Customers quickly lose interest when an item is out of stock or go to a competitor to quench their needs.

Effective inventory management helps ensure that products are available when customers want them.

Reduced Costs

Holding onto inventory can be expensive, considering storage costs, potential obsolescence, and tied-up capital.

To effectively reduce the costs of inventory-associated costs, maintaining a sustainable stock level at all times is necessary.

Increased Profitability

With reduced costs thanks to inventory optimization and increased sales due to enhanced product availability, businesses can see a direct impact on both their top and bottom line.

Key Components of Inventory Management

Stock Review

This involves regularly analyzing stock levels to determine which stocks are still available and which need replenishment.

A regular stock review is necessary to ensure that the numbers on your inventory management system match the stocks available in real life to help meet demand and plan your operations accordingly.

It can also help identify defective stocks in advance to prevent returns due to defects thus increasing overall customer satisfaction rates.

ABC Analysis

Classify inventory based on its significance. 'A' stands for the most valuable items, 'B' for moderate, and 'C' for the least valuable. Note that the word 'valuable' doesn't necessarily equal the item's monetary value, but its contribution to the business's revenue. 'A' items typically account for 80% of the sales, while 'B' and 'C' items account for another 15% and 5%, respectively.

By assigning the relative importance of each item, businesses can judge where to invest in and where to divest from.

With ABC Analysis, you can also come up with strategies like bundling 'C' items with 'A' items to increase the sales of slow-moving or piled-up stocks.

Minimum Order Quantity (MOQ)

The smallest amount of stock a supplier is willing to sell. You have to make orders equal to or larger than the MOQ for the supplier to manufacture the goods your business requests.

Typically, smaller MOQ means higher cost per item and vice versa for larger MOQ. You shouldn't reside with a manufacturer with a larger MOQ just because the cost per item is lower.

Other factors like customer demand, cash flow, and the cost of holding inventory should be considered before choosing which manufacturer is right for your business situation.

Economic Order Quantity (EOQ)

The number of items that should be added to inventory with each order to minimize the total costs of inventory.

If your customer base is large and you experience frequent stock outs, it might be more efficient to order larger quantities at once. Putting factors like customer demand, inventory holding costs, and opportunity costs due to stock outs, calculating the EOQ can be beneficial in improving your business's financial performance.

First-In-First-Out (FIFO)

This principle states that items purchased first will be sold first. It's especially popular among grocery stores that sell perishable items like milk and egg.

It's important to note that FIFO principle is an accounting principle, so you still have to make sure that your inventory stays fresh by selling older items first and newer items last in real practice.

Adopting FIFO principle can also help you make better pricing decisions, as you can see the cost trend of your inventory in a linear timeline.

Safety Stock

Safety stock is an extra stock kept on hand to prevent stockouts. Because customer demand fluctuates, it is important to optimize your inventory levels to follow their needs in real time while reducing costs.

Seasonal factors like weather, holidays, and school starting dates can impact the demand for your business. Thus, investing in safety stock for sudden demand spikes can prevent stockouts and increase customer satisfaction.

Technological Aids for Inventory Management

With the advent of technology, several tools and software solutions can streamline inventory processes. Systems like BoxHero, SAP Business One, and Oracle NetSuite, among others, offer real-time tracking, analytics, and forecasting tools to keep your inventory optimized.

Final Thoughts

Mastering inventory management is an ongoing process. It requires dedication, strategic planning, and sometimes, technological assistance. However, the rewards — in terms of cost savings, customer satisfaction, and overall business efficiency — make it well worth the effort.

Stay ahead in the business game. Dive deep into the realm of inventory management and watch your business thrive in today's competitive landscape.