Sharing Inventory: Collaborative inventory management strategies to reduce inventory burden

Incessantly accumulating inventory is a pain in the neck, interfering with smooth business operations. However, what if this inventory could be shared? The trend of inventory sharing, where companies form cooperative relationships and share inventory, has emerged as a new trend in the commerce industry. What is this 'inventory sharing' trend, which may feel unfamiliar to hear, and what effects does it have?

Emergence of 'Sharing Economy', Inventory Sharing in the Commerce Industry

Do you know the concept of the sharing economy? The sharing economy refers to an economic concept where people share the use of a single item by renting or swapping it instead of owning it directly. This has shifted the paradigm from an economy of 'ownership' to an economy of ‘usage’. The concept of inventory sharing is this paradigm shift applied to the commerce and logistics industry.

There are several methods in inventory sharing. First, there is a cooperation between the wholesaler who manages inventory and the retailers who share the stocks.

For instance, the wholesaler stores a variety of goods in its warehouse. When orders come in, the retailers that have signed a contract with this wholesaler get the goods from the wholesaler's warehouse and send them to the customers. It's literally multiple retail companies 'sharing' the sales rights of the inventory held by the wholesaler. This method of selling goods without inventory is also known as consignment sales or dropshipping.

Through inventory sharing, retailers can present a variety of items to customers without having to bear the burden of the stocks of all products they sell. The wholesaler recovers costs incurred for procurement and inventory management from multiple retailers in sufficient fees.

The second is the 3PL (Third-party Logistics) method where a logistics company provides fulfillment services to sellers. Third-party logistics is the concept of entrusting logistics processes such as delivery and returns to a third party. Examples include FBA (Fulfillment By Amazon) operated by the global e-commerce company Amazon.

Companies providing third-party logistics receive fees and practice inventory sharing by collectively managing the inventory of retailers dealing with the same items during the fulfillment process. In the case of FBA, it asks retailers using third-party logistics whether they want to share inventory with other companies. For retailers with low inventory turnover rates, inventory sharing becomes a good means of dealing with unsold, accumulating inventory.

The third is a method where inventory sharing takes place not between a company managing inventory (wholesaler, logistics company) and retailers, but between multiple retailers. It's the concept of more than two companies forming a contract and co-owning the inventory. For example, suppose Company A and Company B are both selling shoes of Brand C. What would happen if Company A and Company B form a contract to share inventory? Then, each company has a much larger amount of inventory than when they hold inventory individually, but they can handle much higher demand.

Before sharing inventory, Companies A and B had no choice but to 1) notify customers of out-of-stock items while accepting losses or 2) increase inventory levels even considering the remaining inventory to respond to fluctuating customer demand. However, now if Company A runs out of inventory, it can use the inventory of Company B, reducing the cost of having to dispose of excess inventory and out-of-stock notifications that disappoint customers. Also, if the warehouses of the two companies are located in different regions, they can flexibly ship products from the warehouse closer to the customer, significantly reducing delivery time.

Transparent inventory management systems are essential for inventory sharing

For inventory sharing to work, all cooperating companies need to transparently know what inventory is where and how much. Also, they need to maintain appropriate inventory levels according to the demand of all related retailers, requiring more delicate and sophisticated demand forecasting. To make more sophisticated demand forecasts, inventory big data, which can scrutinize past inventory records in detail, is also necessary.

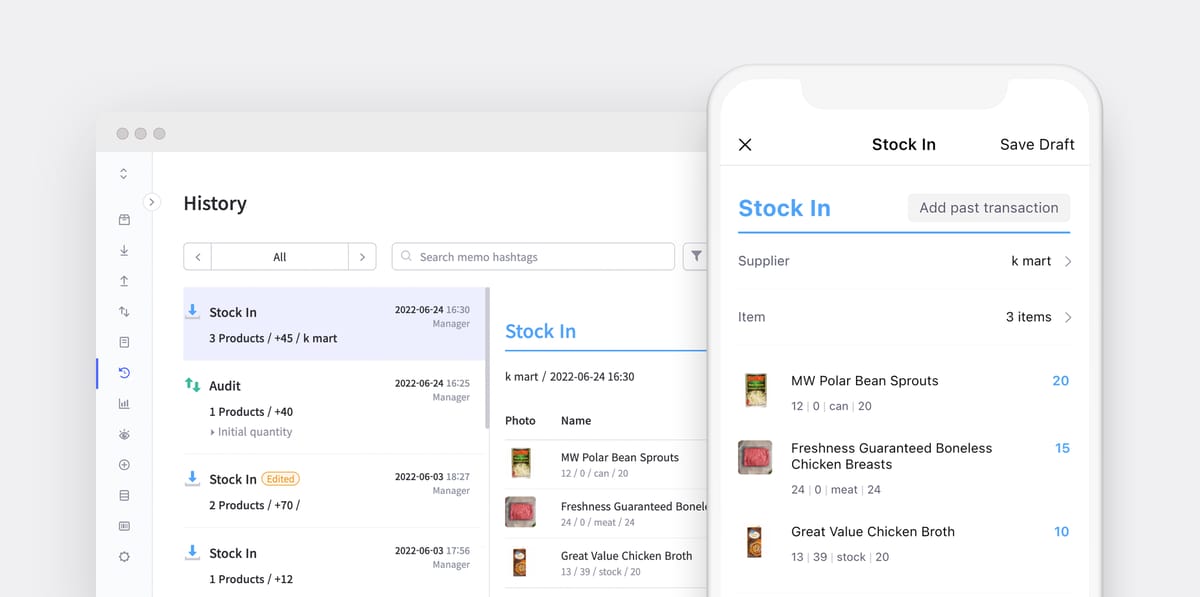

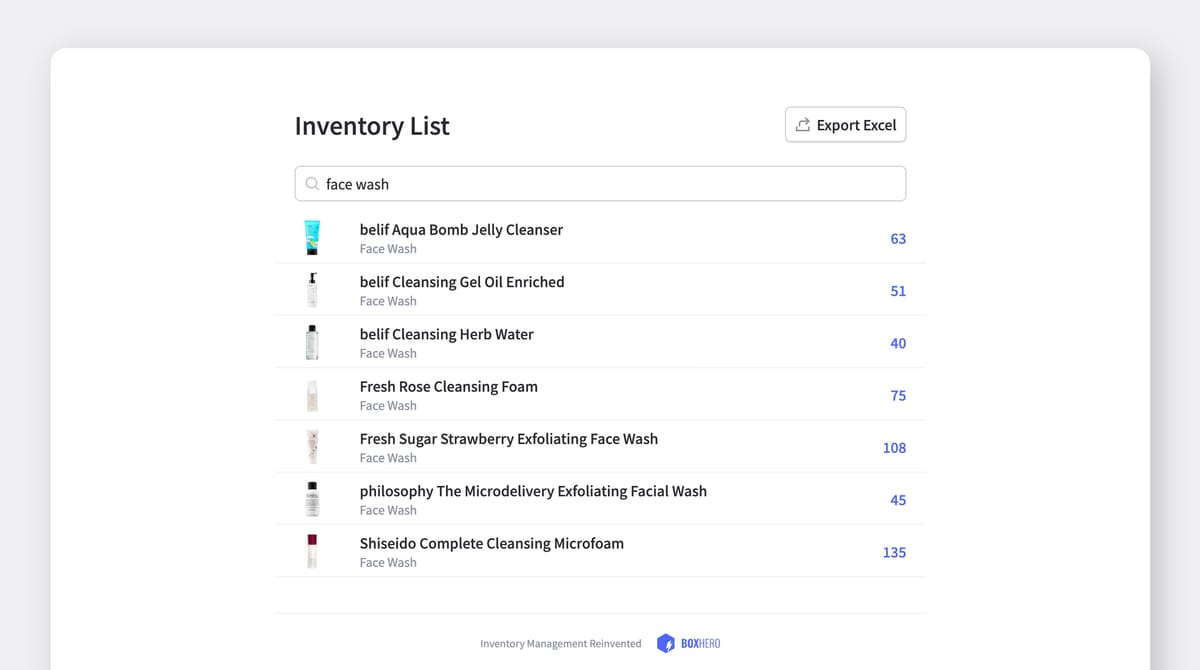

BoxHero is a cloud-based inventory management solution that shares the quantity and location of inventory quickly and easily. As long as you are connected to the Internet, you can check the inventory status anytime, anywhere. Team members can quickly enter inventory information using the convenient UX/UI whenever there are incoming, outgoing, and adjustments. It can also transparently share the inventory status updated in real-time with all members of your organization.

If there is a wholesaler managing the inventory and a retailer referring to the inventory status to request goods (commission model), you can also use the inventory link function to share only the necessary information. Through detailed permission settings, you can share the stock of specific products, or choose not to disclose the exact quantity or price. Even if you are not a team member, anyone with an inventory link URL can check the inventory status in real-time on a PC and mobile.

In addition, the summary and analysis functions in the Reports menu provide data that helps sophisticated demand forecasting, so you can easily build inventory big data.

Inventory has clear benefits, not just risks and burdens. It supports becoming a reliable brand that quickly provides a variety of products that customers want. Establish your own commerce strategy that fully utilizes the benefits of inventory by jumping on the trend of inventory sharing. With an inventory management system like the BoxHero solution, you can explore better inventory sharing options. Try all the features of BoxHero now through a free trial!