Zebra ZD421t Thermal Transfer Printer Overview

In inventory management, the right tools are critical for keeping everything running smoothly. Barcode labels, though small, play a decisive role when it comes to keeping your stock in order.

But have you ever wondered why some labels vanish faster than your morning coffee while others stick around longer than that ancient jar of pickles in your fridge? The secret lies in the printer you choose.

Thermal transfer printers, especially models like the Zebra ZD421t, offer a reliable solution for creating durable labels that can stand up to the demands of inventory management. Whether you're dealing with temperature changes, moisture, or daily wear and tear, choosing the right printer can help ensure your labels last and stay readable.

In this article, we discuss thermal printers and types and closely examine why the Zebra ZD421t is a top choice for inventory managers.

What is a Thermal Printer? Types Of Thermal Printers

A thermal printer uses heat to create images on heat-sensitive paper. This technology removes the need for ink or toner cartridges, making them a cost-effective and environmentally friendly option.

Let's explore the two primary types of thermal printers, thermal transfer and direct thermal, to understand their functionalities and identify which might suit various applications.

A) Thermal Transfer Printers

Thermal transfer printers are devices that use heat to transfer ink from a wax-based or resin-based ribbon onto a label. This technique is renowned for producing durable and long-lasting labels.

The ribbon acts as a critical intermediary that ensures high-quality prints and protects the print head from wear and tear, extending its lifespan and maintaining print clarity.

How It Works: A thermal print head applies heat to a ribbon, which melts ink onto the label material, creating a permanent mark. The ribbon serves as a buffer between the print head and the label, enhancing print quality and label durability.

✅ Pros:

- Produces labels that can withstand extreme conditions such as heat, chemicals, and abrasion.

- Capable of printing in color with different colored ribbons.

- Suitable for detailed graphics and two-dimensional barcodes.

❌ Cons:

- Higher setup cost due to the need for ribbons.

- Requires more maintenance to manage ribbon supply.

📦 Use Cases:

- Ideal for asset tagging in industries where items are exposed to harsh environments.

- Suitable for outdoor labeling, such as nursery plant tags or outdoor equipment.

- Recommended for healthcare settings for labeling specimens and pharmacy items due to the need for labels that withstand sterilization processes.

B) Direct Thermal Printers

Direct thermal printers create labels by applying heat directly onto heat-sensitive paper. This method is effective for short-term label applications where durability is less of a concern.

How It Works: The printer's thermal printhead heats specific areas of the heat-sensitive paper, turning them black to create images or text. No ink or ribbon is involved in this process.

✅ Pros:

- Lower operational costs since there are no ribbons or ink cartridges to replace.

- Easier maintenance with fewer moving parts.

❌ Cons:

- Labels are susceptible to fading and degradation if exposed to heat, sunlight, or harsh conditions.

- Limited to printing on paper, reducing durability and versatility.

- Cannot print in color, which may be a limitation for certain applications.

📦 Use Cases:

- Commonly used for grocery store receipt printing, where label longevity is not critical.

- Suitable for shipping labels that only need to last until the package reaches its destination.

- Often used in environments with controlled conditions, such as office settings for printing visitor badges or appointment cards.

| Thermal Transfer Printer | Direct Thermal Printer | |

|---|---|---|

| Ink Application | Uses ribbons to transfer ink | No ribbons; heats the label directly |

| Durability of Labels | High; resistant to heat, UV light, chemicals, and abrasion | Lower; susceptible to fading and damage from heat and light |

| Print Longevity | Long-lasting; suitable for permanent labeling needs | Short-term; best for labels with a limited lifespan |

| Material Compatibility | Versatile; performs on a variety of materials, including synthetics | Limited to heat-sensitive paper |

| Heat Resistance | Excellent | Poor (image darkens with heat) |

| Light Resistance | Excellent | Poor (fades in sunlight) |

| Moisture Resistance | Good to Excellent | Poor to Fair |

| Operational Cost | Higher initial cost due to need for ribbons | Lower initial cost; no ribbons required |

| Use Cases | Asset tagging in industrial settings, outdoor labels, labels exposed to harsh conditions | Receipts, food packaging labels, shipping labels with a short transit time |

Why Choose Thermal Transfer Printers for Inventory Management?

The global thermal transfer printer market, valued at USD 45.5 billion in 2022, is projected to reach USD 63.35 billion by 2030, growing at a 4.23% CAGR from 2023 to 2030. This change is fueled by increasing demand for high-quality labeling in industries such as manufacturing, healthcare, logistics, and retail.

Thermal transfer printers bring several benefits that are particularly valuable in inventory management contexts, where label durability, clarity, and flexibility are crucial. Here’s why they stand out as the preferred choice:

Durability & Longevity

In a warehouse or storage environment, labels need to withstand various challenges:

- Temperature fluctuations: From cold storage to warm shipping areas

- Moisture exposure: Humidity, condensation, or occasional splashes

- Physical wear: Friction from handling and transportation

Thermal transfer labels excel in these conditions. The ink is bonded to the label material at a molecular level, creating a print that's highly resistant to fading, smudging, or wearing off. This durability translates to:

- Consistently scannable barcodes, reducing errors in inventory tracking

- Less frequent need for label replacement, saving time and resources

- Reliable identification of items, even after long-term storage

While the initial investment in a thermal transfer printer and supplies may be higher, the long-term value is clear. You'll spend less time and money replacing faded or damaged labels, and you'll have fewer issues with misidentified inventory.

Accuracy & Readability

Clear, readable labels are vital for efficient inventory management. Thermal transfer printers deliver on this front in several ways:

- High contrast prints: The sharp black-on-white (or other color combinations) makes for easy reading by both humans and barcode scanners.

- Consistent quality: Unlike some printing methods, thermal transfer maintains its clarity from the first label to the last in a batch.

- Fine detail capabilities: Essential for printing small barcodes or detailed product information.

These features contribute to faster, more accurate scanning processes, reduced errors in manual reading of labels, and improved overall efficiency in inventory tracking and management.

📚Read more: 5 Best Inventory Management Software With Barcode Scanning

Compatibility with Various Materials

One of the outstanding features of thermal transfer printers is their versatility when it comes to label materials. They are compatible with a wide range of materials, including:

- Paper: Various types of paper, such as plain paper, glossy paper, and coated paper.

- Polyester: Polyester films and fabrics for labels, tags, and banners.

- Vinyl: Vinyl films for durable labels and decals.

- Polypropylene: Polypropylene films for waterproof labels and tags.

- Nylon: Nylon fabrics for clothing labels and tags.

- Polyamide: Polyamide films for high-temperature resistant labels.

Whether for freezing conditions or heat-exposed environments, there’s a label material and ribbon combination that fits, enhancing the flexibility of your inventory management system.

The specific material compatibility depends on the type of ribbon used in the thermal transfer printer. Different ribbons are designed to work with different materials and provide varying levels of durability and print quality.

The Zebra ZD421t Thermal Transfer Printer

The Zebra ZD421t is a high-performance thermal transfer printer designed to meet the demanding needs of modern inventory management. Known for its reliability and user-friendly features, this printer represents the latest in Zebra's long line of quality printing solutions.

Key Features

1. Design and Performance:

Developed with user convenience in mind, this printer is compact and easy to integrate into any workspace

- Print resolution: Up to 300 dpi for crisp, clear barcodes and text

- Print speed: Up to 8 inches per second for efficient label production

- Media capacity: Accommodates large rolls of labels, reducing downtime for reloading

- Print Quality: Automatic print darkness adjustment for consistent output quality

2. Connectivity Options:

Offers multiple connectivity options facilitating easy integration into existing systems.

- USB 2.0, USB Host, Ethernet, and Serial ports come standard

- Optional Bluetooth Low Energy and Wi-Fi for wireless printing capabilities

- Mobile printing support for added flexibility in label creation and printing

3. User-Friendly Interface:

- 4.3" full-color LCD touch display for easy navigation and printer status updates

- LED status indicators for at-a-glance printer diagnostics

- Tool-less platen and printhead replacement for easy maintenance

4. Durability:

Built to last, the ZD421t is constructed with premium materials that can endure the rigors of industrial environments. It's designed to handle high-volume printing tasks consistently, making it an ideal choice for businesses that require reliable output over extended periods.

- Dual-wall frame construction for enhanced durability in demanding environments

- Moveable media sensor for compatibility with various label types and sizes

5. Print Quality

Ensures crisp, clear prints essential for accurate barcode reading and inventory management.

- Automatic print darkness adjustment for consistent output quality

- 300 dpi print resolution option for small labels or intricate designs

6. Innovative Features

The ZD421t also includes forward-thinking features such as a movable sensor for comprehensive media compatibility and a peel-and-present model.

Zebra ZD421t Printer Review

Eli Itzhaki, the CEO and Founder of Keyzoo shared his experience of using Zebra ZD421t with us:

"A colleague of mine recommended the Zebra ZD421t thermal transfer printer, and it’s been a solid addition to our operations….Before switching to the Zebra ZD421t… I remember we had an issue where a batch of labels printed with our old system became unreadable after a month in storage. That meant reprinting and reapplying all those labels, which was a headache and a waste of resources. Since we started using the Zebra, that problem has been eliminated.

What’s also worth mentioning is the printer's ability to handle different label sizes. We have a variety of products, from small lock components to larger items like safes, and each requires a different label size. The ZD421t allows us to switch between these sizes without needing to recalibrate or make manual adjustments each time. This saves us a lot of time and prevents errors that could occur with a less adaptable printer."

Practical Setup for the Zebra ZD421t

The Zebra ZD421t from Zebra Technologies is designed with user-friendliness in mind, ensuring that setup and operation are straightforward, even for those new to thermal transfer printing. Here's how to get started:

Unboxing and Setup

- Contents: The ZD421t package includes the printer itself, a quick start guide, USB cable, power supply, and power cord, along with a ribbon core and ribbon adapters.

- Initial Setup: To begin using the printer, simply unlock and open the printer cover, load the roll of labels, and insert the ribbon roll onto the provided ribbon core and adapters.

- Power Connection and Initialization: Connect the printer to a power source. Once powered on, the printer status light should turn green if everything is set up correctly, indicating that the printer is ready for use.

Operating the Printer

During operation, keep an eye on the printer status light. When the media (labels or ribbon) runs out, the light will turn red. To replace, open the printer, discard the empty roll, and set up a new one. For thermal transfer printing, ensure that the ribbon is also replaced by pushing the ribbon core into place, securing the new ribbon.

Zebra Printer Integration with BoxHero

By combining the Zebra ZD421t's printing prowess with BoxHero's comprehensive inventory management features, you create a powerful system for maintaining accurate, up-to-date inventory records. This integration streamlines your labeling process, reduces errors, and provides the durability and clarity needed for long-term inventory tracking.

Here's how you can leverage this robust combination:

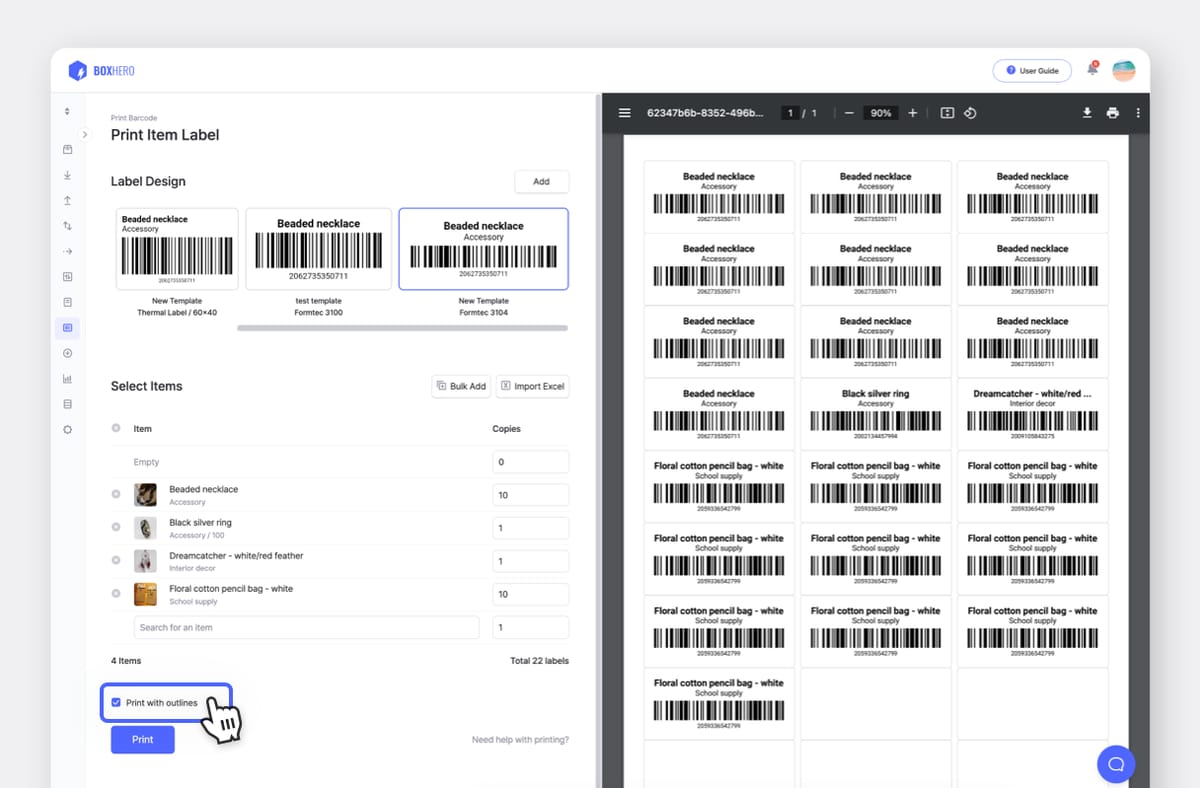

Label Generation

Using BoxHero's intuitive interface, you can design custom labels that include all necessary inventory information such as barcodes, QR codes, item names, SKUs, and other relevant data. BoxHero allows you to customize the label size and layout to suit your specific needs, ensuring that your labels are both functional and aesthetically pleasing.

Printing Process

Once your labels are designed in BoxHero, you can send print jobs directly to the Zebra ZD421t. The printer's high-speed capabilities allow for the quick production of large batches of labels, making it ideal for high-volume environments. The color touch display on the printer facilitates easy management of print jobs and allows for any last-minute adjustments before the final printing process.

Label Application

The durable, high-quality labels produced by the ZD421t can be applied to your inventory items. Thanks to the thermal transfer technology, these labels will remain legible and scannable even under challenging warehouse conditions, such as exposure to dust, moisture, and varying temperatures.

Inventory Tracking

With the labels in place, use BoxHero's mobile app to scan the barcodes on your newly labeled items. This lets you update inventory counts, locations, and other details in real time. The clear, durable labels produced by the ZD421t ensure consistent scannability, reducing errors in your inventory tracking and improving overall operational efficiency.

Reporting and Analytics

Accurate labeling and tracking enable the generation of precise inventory reports through BoxHero. These insights can help you optimize your stock levels, spot trends, and make informed business decisions, thereby enhancing the overall management of your resources.

Scalability

As your inventory grows, the ZD421t's robust construction and high-volume printing capabilities can keep pace with your expanding business needs. You can easily print new labels for new products or locations as your business expands, ensuring that your labeling system scales smoothly with your operational growth.

BoxHero: An Official Zebra Partner

Final Thoughts

The Zebra ZD421t's versatility, coupled with BoxHero's user-friendly interface, makes this combination suitable for businesses of various sizes and across different industries. Whether you're managing a small stockroom or overseeing a large warehouse, this printer-software duo offers the tools you need for effective inventory management.