Warehouse Space Management Made Easy with Inventory Management Software

As the new year starts, people's social media are flooded with the classic January tagline "new year, new me", overlaid with pictures of healthy meals, exercise, or a clean house. Whether or not there's something magical about January, it's probably not a bad time for businesses to examine some of the challenges faced in the prior years and set new goals or processes in place. Maybe you are envisioning a transformation of a messy, chaotic warehouse into an organized distribution center that brings you a sense of calm. Who wouldn't love to start the new year with a clean slate (warehouse) and keep it that way without having to expand your existing warehouse space? Inventory management software can help.

Warehouse Space Utilization

The definition of warehouse space utilization can be used synonymously with warehouse space optimization in that both terms can indicate how well a company makes use of a given warehouse space. Putting aside the physical and somewhat obvious aspect of cleaning up the warehouse floor to gain valuable space, or utilizing available vertical space, you can also have successful warehouse management by improving forecast accuracy and reducing excess inventory. For example, only allow active stock in the warehouse with inventory on hand for SKUs incurring demand within the previous twelve months. A business can optimize warehouse operations by minimizing storage of unsellable, damaged, leftover seasonal products, or inventory commonly referred to as "dead stock" resulting from an inadequate inventory management system. We'll cover the key benefits that inventory management software provides to limit dead stock and hit optimal safety stock quantities.

Maximizing Warehouse Storage Space Utilization with Inventory Management System

Imagine using a manual process to chart out a map of the warehouse, and allocate spaces for inventories. It's a daunting task that probably took up a lot of time and resources for businesses before the advancement and availability of technology. Thankfully, there are plenty of tools and tactics that modern retailers employ to limit their dead stock while hitting optimal safety stock quantities. When businesses automate certain inventory management processes, it reduces human error, minimizes labor costs, and produces more accurate stock counts. This reduction in a business's dependence on manual and outdated processes will make the inventory management process more efficient in the long term.

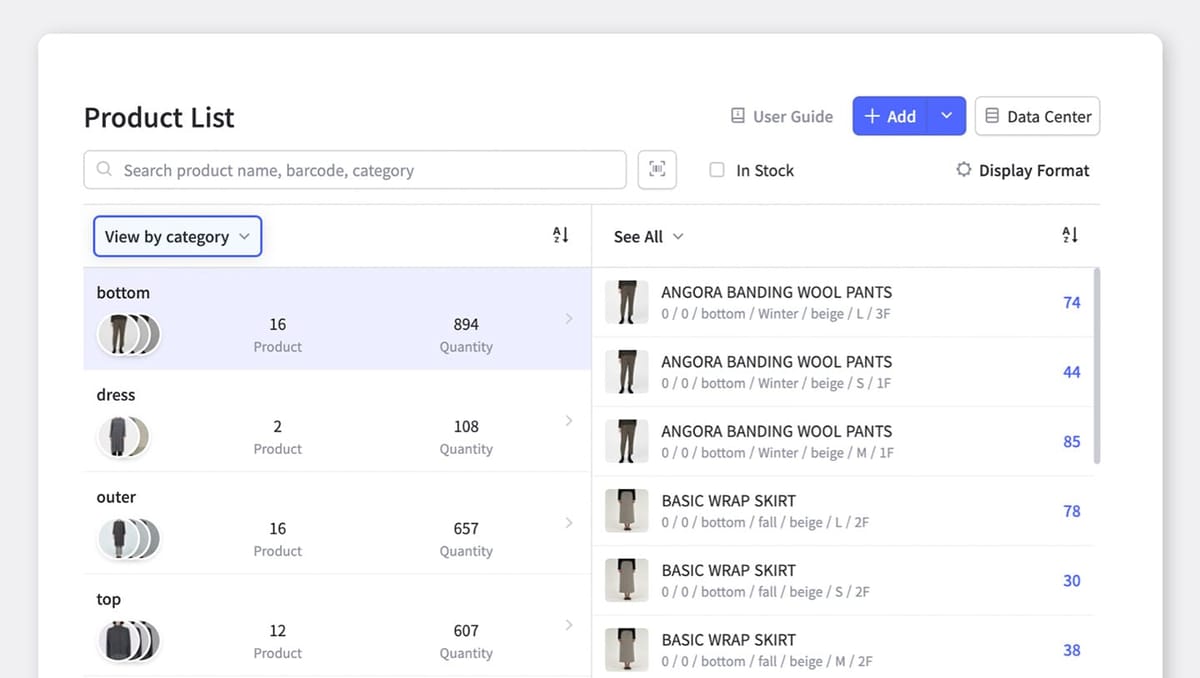

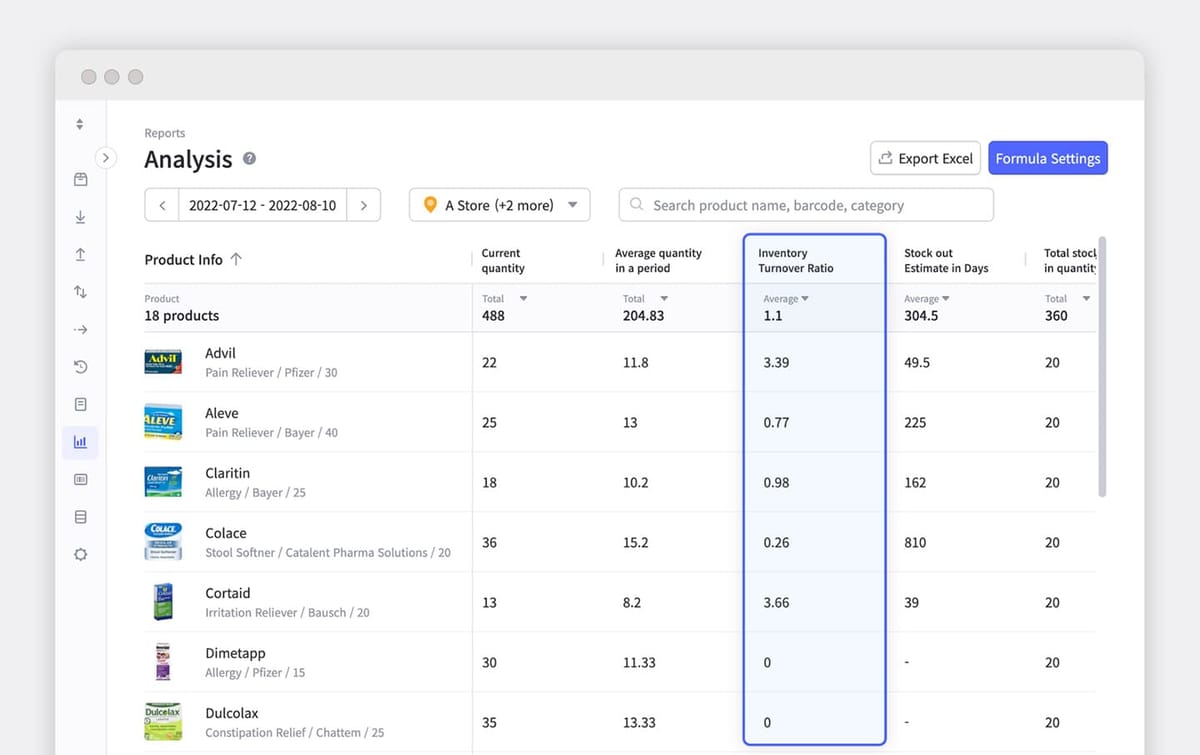

Identify Obsolete Inventory

Unaudited forecasting can lead to excessive amounts of inventory, which may complicate the warehouse inventory management process. Implementing effective inventory control measures by empowering you and your staff to consistently use inventory management software will increase forecast accuracy. This, in turn, will allow users to quickly identify obsolete inventory and mitigate against the accumulation of dead stock potentially taking up warehouse space.

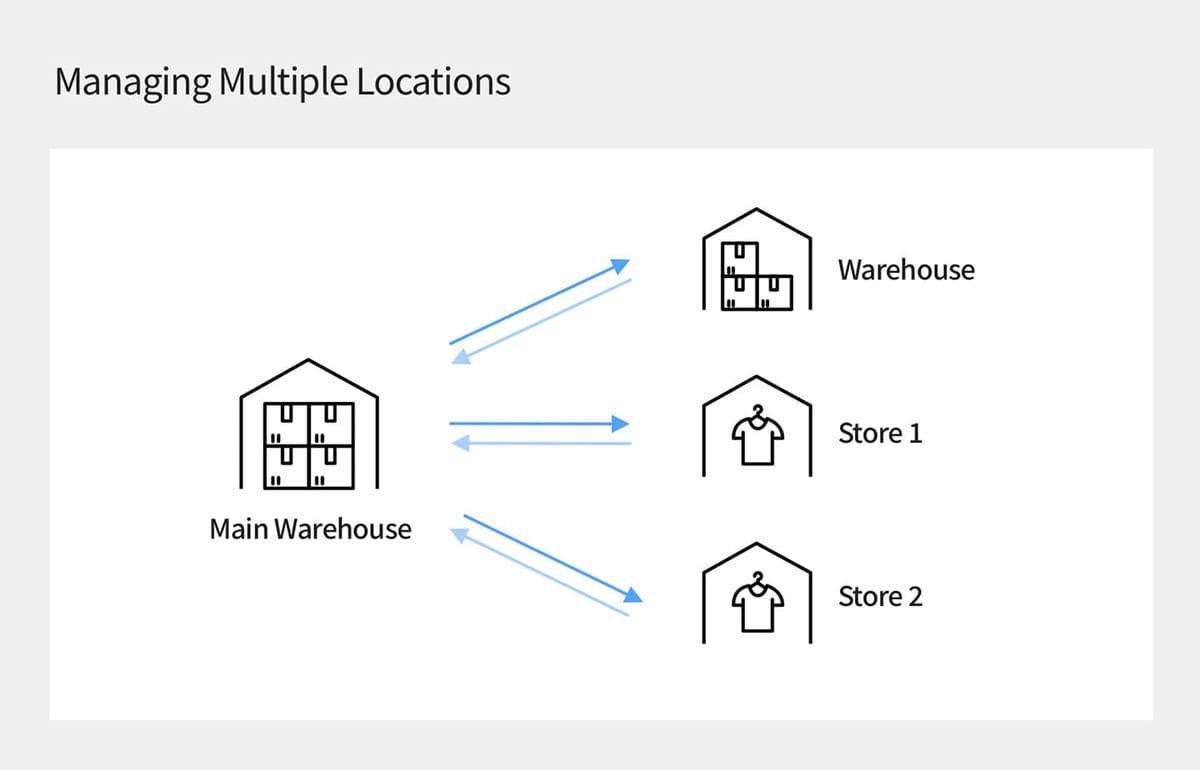

Improved Coordination Among Warehouses

Another way that inventory management software can help with warehouse space optimization is by helping companies organize and improve coordination between different facilities. Having multiple warehouses or retail locations is quite common for businesses, and there needs to be a warehouse space management system in place to allow for a higher volume of inventory to be managed more efficiently. Inventory management software is now compatible with mobile devices, allowing for greater mobility and coordination between locations to update transactions in real time.

Take, for example, a shoe store with multiple retail locations. When one location runs low on stock for a certain style of shoes, it might need to order more shoes from another location. An inventory management system can show the store employee which locations have the particular style of shoes, how many are in the system and what they cost. The employee can then place an order through the system, which automatically updates the inventory count at each location. The result is lowered cost, improved sales, increased brand image, and attraction of new customers.

Greater Organization

Getting organized at the beginning of the year may be one of the goals that companies have in order to set the right "tone" for the upcoming year and save existing warehouse space. The customized inventory management system can help businesses create better internal organizational systems, allowing employees to set useful parameters to categorize products as necessary. Companies operating with efficient inventory management system is in sync with the timing of inventory delivery to the warehouse, helping businesses fulfill orders quickly and accurately. If you haven't done so already, start automating your inventory management process and try the BoxHero app.